Best Contractor Table Saws (2025 Buyer’s Guide)

Looking for the best contractor table saws? Here’s a casual, no-nonsense guide to what to look for, which models are worth your money, and how to pick the right saw for your shop or job site.

The best contractor table saws sit between portable jobsite saws and heavy cabinet saws: they give you more power and a larger table than compact jobsite models, but they’re more affordable and (usually) easier to move than a full cabinet saw.

If you do a lot of serious hobby work, occasional furniture builds, or light contracting, a contractor saw can be one of the best investments for your workshop.

Below I’ll explain the key features to evaluate, the trade-offs, and a short roundup of standouts people actually buy and like in 2025.

What makes a contractor table saw different?

The best contractor table saws tend to have larger tables, heavier frames, and more cutting power than small jobsite saws, but they’re not as massive or permanently installed as cabinet saws. They usually have:

- a beefier, better motor (for ripping hardwoods)

- a wider rip capacity (so you can cut wider boards)

- a more stable table and better fence than entry-level saws

They’re great if you want accurate, repeatable cuts but don’t have the space (or budget) for a cabinet saw. If you mostly need ultimate portability, a jobsite saw might still be a better choice.

If you have the space and want to be able to rip large sheets of plywood, than you probably want to consider the more expensive cabinet saws.

Key features to look for when shopping contractor table saws

1. Motor power & type: More amps (or horsepower in 240V models) helps when ripping thick hardwood; look for at least a strong 1.5–2.0 HP equivalent if you’ll be cutting lot of hardwood.

2. Table surface and build quality: Cast-iron tops resist vibration and stay true; steel tops are okay, but heavier cast surfaces offer overall better stability.

3. Rip capacity: This determines the widest cut you can make in one pass. If you want to rip 8–12″ boards, check specs carefully.

4. Fence quality: A racking, locking fence that stays square makes accurate cuts easy. Cheap fences can create a lot of frustration. One of the key features I thought about when purchasing my DeWalt contractor table saw was the quality of it’s fence.

5. Miter gauge & dado capability: If you use crosscuts or dadoes frequently, confirm dado blade compatibility and quality miter gauge. Most major brands, like DeWalt, will accept dado blades, but some of the smaller models may not work or fit dados.

6. Safety features & dust collection: Look for good blade guards, anti-kickback pawls, and decent dust ports. Dust control is often the overlooked factor that keeps a shop both clean and safe. SawStop also offers the only anti-cut protection and now comes in a contractor sized option.

7. Portability & footprint: Contractor saws vary: some are reasonably mobile; others are heavy and more “shop anchored.” Think about where it will live and whether you need to move it. Some also come with a folding, rolling stand or you can get it as an extra feature. This is also a major selling point of my DeWalt contractor table saw. I can roll it out and tuck it back into its spot in my small shop with minimal effort.

Budget tiers

- Under $500 – You’ll find entry-level contractor-style saws, but watch for flimsy fences or small motors. These are okay if you’re learning or building small pieces, but if you intend to do a a lot of work these can turn a 250ish dollar machine into a piece of junk very quickly.

- $500–$1,000 – The sweet spot for hobbyists and contractors alike. These table saws offer better motors, stronger fences, and more stable tables. Many popular contractor saws sit in this general range. Sometimes, you might get a good sale on a contractor table saw that puts it below this price range.

- $1,000+ – You’re getting pro features: cast-iron tables, precision fences, and sometimes hybrid/cabinet features in contractor footprints. You can also take advantage of some of the safest options in this range, like the SawStop mentioned earlier.

Top picks & what makes them stand out

Below are models and brands that consistently appear in “best” lists and buyer conversations in 2025. Links go to manufacturer or review pages so you can check current pricing, specs, and accessories. (I do not get any sort of kick backs, so feel free to click around and check out what makes sense to you.)

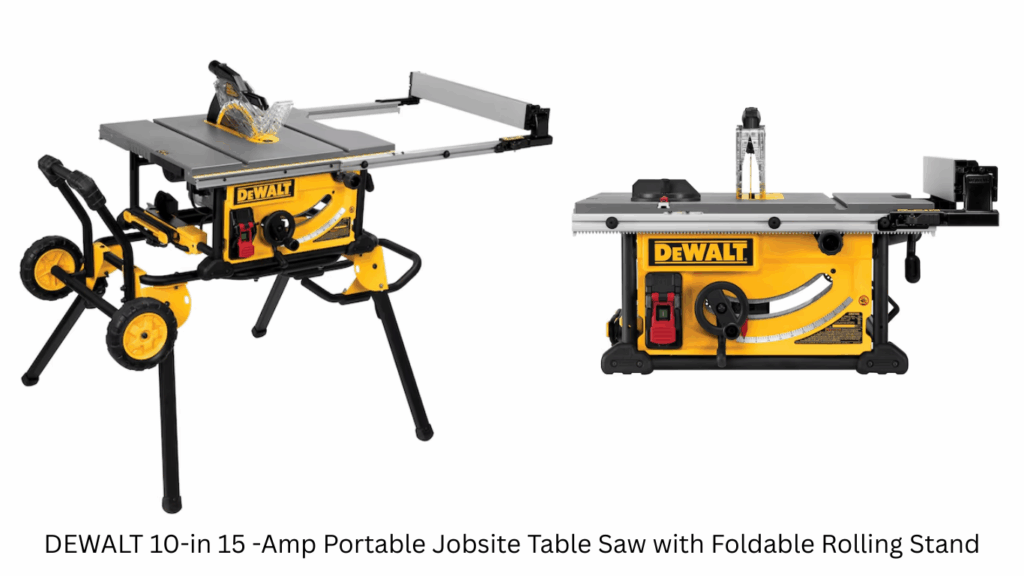

DEWALT DWE7491RS – A reliable rip-and-go (compact contractor / jobsite hybrid)

A long-running favorite for folks who need rip capacity and portability. The DWE7491RS gives a wide rip, solid motor, and a rolling stand option for moving it around a job site or garage. If you want something that’s a great all-around workhorse, this is a top pick.

The folding table is particularly helpful for tight spaces, like my own shop. I don’t need to have a work desk space ready and clear for it, nor do I have to get on the ground to run the machine.

It also has a variety of features, including:

- ratcheting fence movement, for precise fence placement

- extending fence features

- comes with a starter 10 inch blade

- push bar comes included with its own holder

- accepts dado blades

You can get DeWalt from a lot of retailers, but Lowes is often a good option.

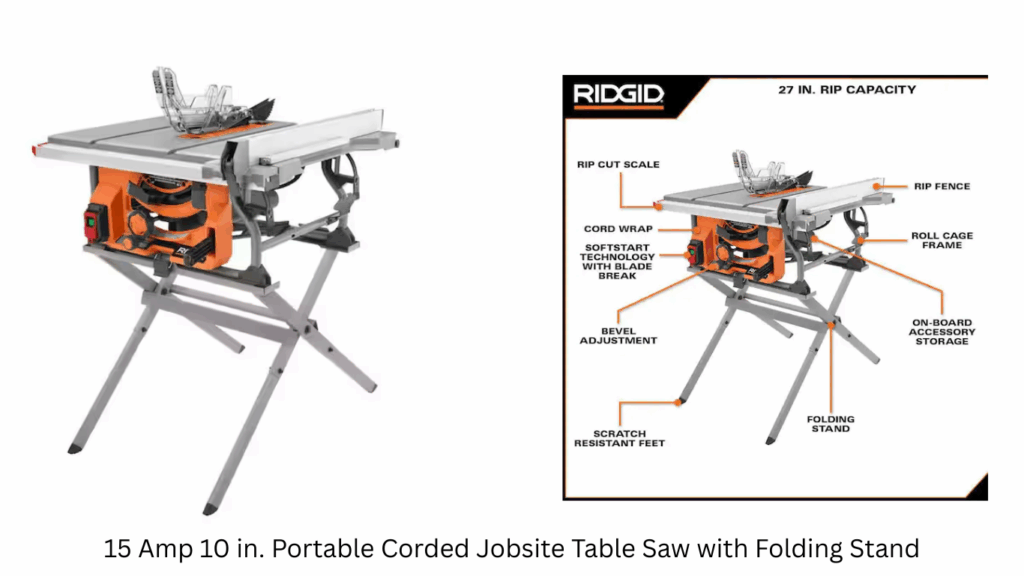

RIDGID 10-in. Contractor Table Saw (R4560) – Value + cast-iron top option

RIDGID’s contractor saws (some with cast-iron tops and matching price tag) get praise for feel and value; users often note excellent fence action and good alignment options after a little setup.

This table saw is solid choice if you want a durable shop saw without paying cabinet-saw money.

My dad has this model and has no complaints. He settled on it after his 30 plus year old Craftsman finally died on him.

Rigid is available at Home Depot and other retailers.

WEN 8.25″ Compact Benchtop Model – Budget-friendly and capable

WEN’s compact bench top or mini-contractor options give you a lot of capability for the price and are perfect if you need a saw for small furniture, jigs, and consistent trim work. Expect a smaller table and less raw power than the biggest contractor saws, but great value overall.

You also don’t get some of the bells and whistles you might expect, like a dedicated stand. It also does not have as wide a rip capacity, at about 25 inches. It does include a miter push bar, stable fence, and beveling capabilities.

There are several other lower budget options, like Ryobi brand or ones you can get at discount stores, like Harbor Freight.

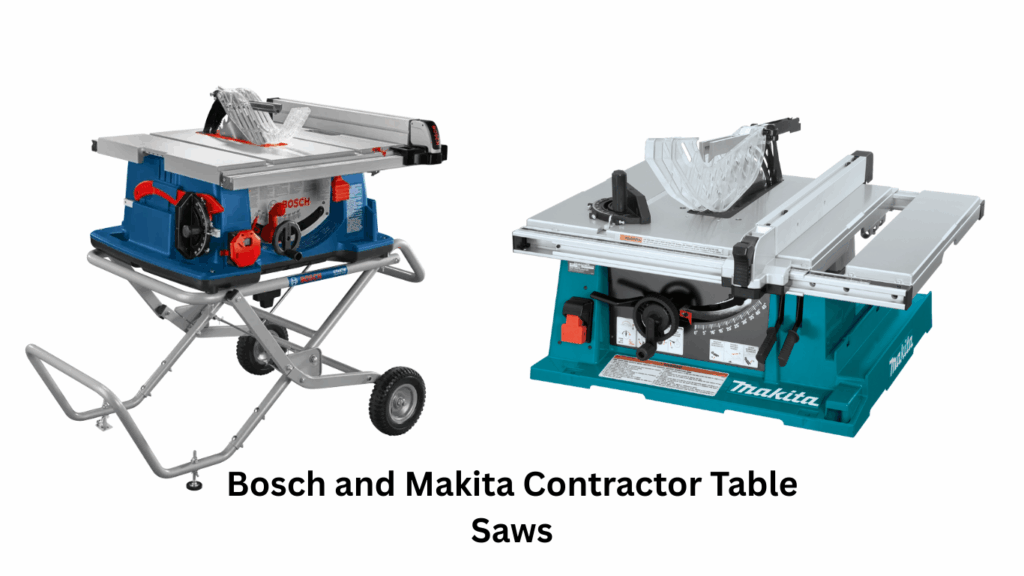

Bosch & Makita Compact Contractor and Portable Saws – Engineered for pros

Bosch ( with its gravity-rise stands and other features) and Makita bring excellent engineering, reliable fences, and good dust control in compact packages. They often cost a bit more but are rock-solid performers for pros who move their saw frequently.

These are generally considered professional grade and top choices for anyone who makes their living as a contractor. They may be a bit over-kill for the casual wood worker.

SawStop Contractor Offerings (if safety-first is a must)

If you want contractor-level performance with SawStop’s famous blade-stopping safety technology, the hybrid/contractor options from SawStop are worth a look. These are especially helpful if you work solo or with less-than-ideal shop help.

Make no mistake, these cost more, but they add a level of safety unmatched on the market. In fact, SawStop is frequently recommended in ‘best of’ lists when safety is weighted highly.

In case you are not aware, these saws have built in sensors and a blade stop that will dead stop the blade the second it detects contact with flesh. This saves you both expensive medical care and all your digits.

Real-world buyer tips & setup advice

- Measure your workshop first. Don’t guess: mock up the footprint and clearance for ripping long boards. A saw with great specs can still be a poor fit in a cramped shop. Keep in mind you need both some space to the sides and also out the back of the saw, particularly if ripping long pieces of lumber.

- Budget for accessories. A good blade, a quality miter gauge, a crosscut sled, and a dado set (if you use them) are extra costs that may be worth it for you. Make sure to double check your dado stack and your needs before purchasing a saw.

- Calibrate when you receive it. Factory alignment is rarely perfect; square the blade to the miter slot and check fence alignment before heavy use. You’ll get vastly better results and less frustration.

- Use a good blade for the job. The cheap blade that comes with a saw will cut, but a quality general-purpose 40–50T carbide blade will change your life. Good blades are often more expensive, but they do a much better job making clean, easy cuts.

- Dust collection matters. Even contractor saws can be set up to connect to a shop vac or dust collector. You should take advantage of the feature to save your lungs and your floor.

Should you buy a contractor saw in 2025?

If you’re building solid wood furniture, doing regular shop production, or want a step-up tool from hand or even smaller portable saws without the cabinet price tag, than yes, contractor table saws are a practical choice.

If your work is mostly ripping plywood sheets or you need the quiet and dust control of a cabinet saw and have the space for it, you may want to save up.

Final thought: Match the saw to your work

The “best contractor table saws” aren’t the same for everyone. Choose a saw that matches the material sizes you’ll cut most often, the accuracy you need, and the space you have.

If you find yourself torn between two models, consider: which one will make your workflow easier tomorrow? Often that practical answer beats specs on paper.